What is CMMS?

A CMMS software is a system that keeps track of every work order, piece of equipment, and spare part in one place.

What is CMMS - A 2 minute explainer

Instead of relying on spreadsheets or memory, maintenance teams use a CMMS to plan preventive work, respond to breakdowns faster, and make sure nothing slips through the cracks.

At its core, a CMMS gives you a complete picture of your assets and maintenance activities, what’s due, what’s in progress, and what it costs.

Many modern maintenance software add mobile access, IoT connectivity, and analytics, turning raw maintenance data into insights. Facility managers can use this data to cut downtime, extend asset life, and prove the value of their maintenance program.

- Consolidates all maintenance-related information in one centralized system

- Brings structure and visibility to maintenance operations across the organization

- Simplifies coordination between teams, tools, and timelines

- Enhances decision-making with real-time insights and historical data

How CMMS software works

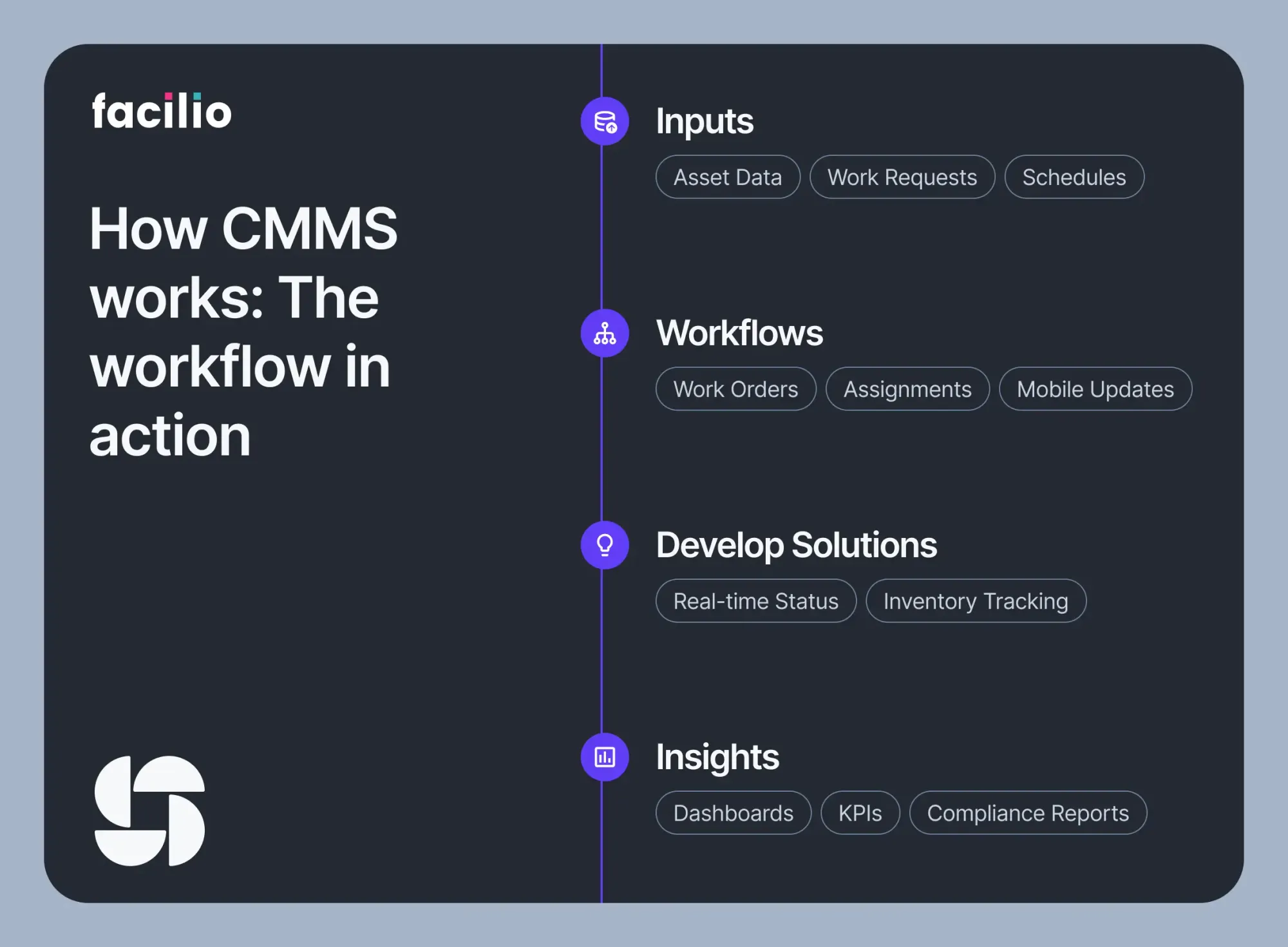

A CMMS works by capturing maintenance information, organizing it in one place, and turning it into tasks, alerts, and insights that keep facilities running smoothly.

Here’s how it functions across different dimensions:

1. Data inputs

- Asset registry: Every piece of equipment, building system, and spare part is recorded in the CMMS with details like make, model, purchase date, and service history.

- Maintenance requests: Teams can log issues manually, through mobile apps, or even via automated IoT alerts.

- Schedules and standards: Preventive maintenance plans, OEM recommendations, and compliance requirements are uploaded into the system.

2. Task management & workflows

- Work order creation: Jobs are generated automatically (based on time, usage, or condition triggers) or manually by supervisors.

- Assignment & notifications: Tasks are assigned to technicians with clear instructions, priority levels, and deadlines. Notifications ensure nothing is missed.

- Mobile execution: Technicians update work orders on-site via a mobile CMMS app, capturing notes, photos, parts used, and time spent.

3. Real-time monitoring

- Live status tracking: Managers can see which tasks are pending, in progress, or completed.

- Parts and inventory control: The system keeps tabs on spare parts usage, stock levels, and reordering needs.

- Downtime logging: Equipment availability and mean time between failures (MTBF) are automatically tracked.

4. Analytics and reporting

- Performance dashboards: KPIs like response times, preventive vs. reactive ratio, and maintenance costs are visualized with intuitive CMMS reports and dashboardslowers.

- Trend analysis: Historical data reveals recurring issues, weak spots, or underperforming assets.

- Compliance reports: CMMS generates audit-ready logs for industries that require regulatory compliance.

5. Extensions of modern CMMS

- IoT integration: Sensors feed real-time equipment data (temperature, vibration, run hours) to trigger predictive maintenance.

- Multi-site visibility: For organizations with multiple facilities, the CMMS provides portfolio-wide insights.

- Sustainability tracking: Some systems tie maintenance data to energy use, emissions, or lifecycle assessments.

What are the benefits of having a CMMS?

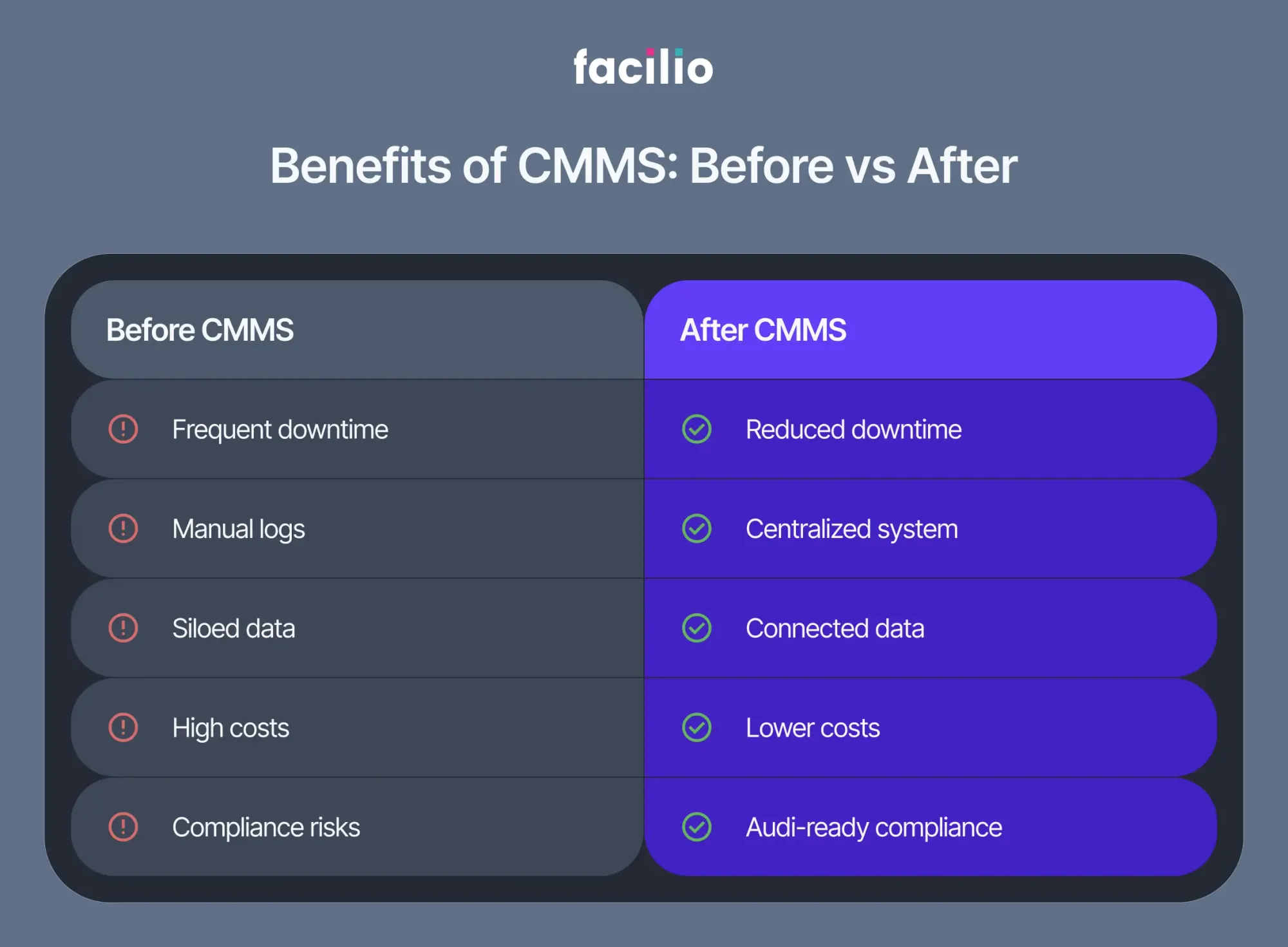

A well-implemented CMMS system does more than organize work orders; it transforms how maintenance teams operate.

Key benefits of CMMS software include:

a) Reduces downtime - Automated preventive schedules and alerts catch issues early, minimizing costly breakdowns.

b) Extends asset life - Consistent servicing and full maintenance history keep equipment in better shape for longer.

c) Improves compliance and safety - Audit-ready logs and inspection records help meet regulatory standards and reduce risk.

d) Cuts maintenance costs - Optimized spare parts management and efficient scheduling lower emergency and overtime expenses.

e) Boosts workforce productivity - Clear digital work orders (often mobile-enabled) reduce paperwork and wasted time.

f) Supports sustainability goals - Extending asset life and reducing waste helps organizations meet their sustainability targets.

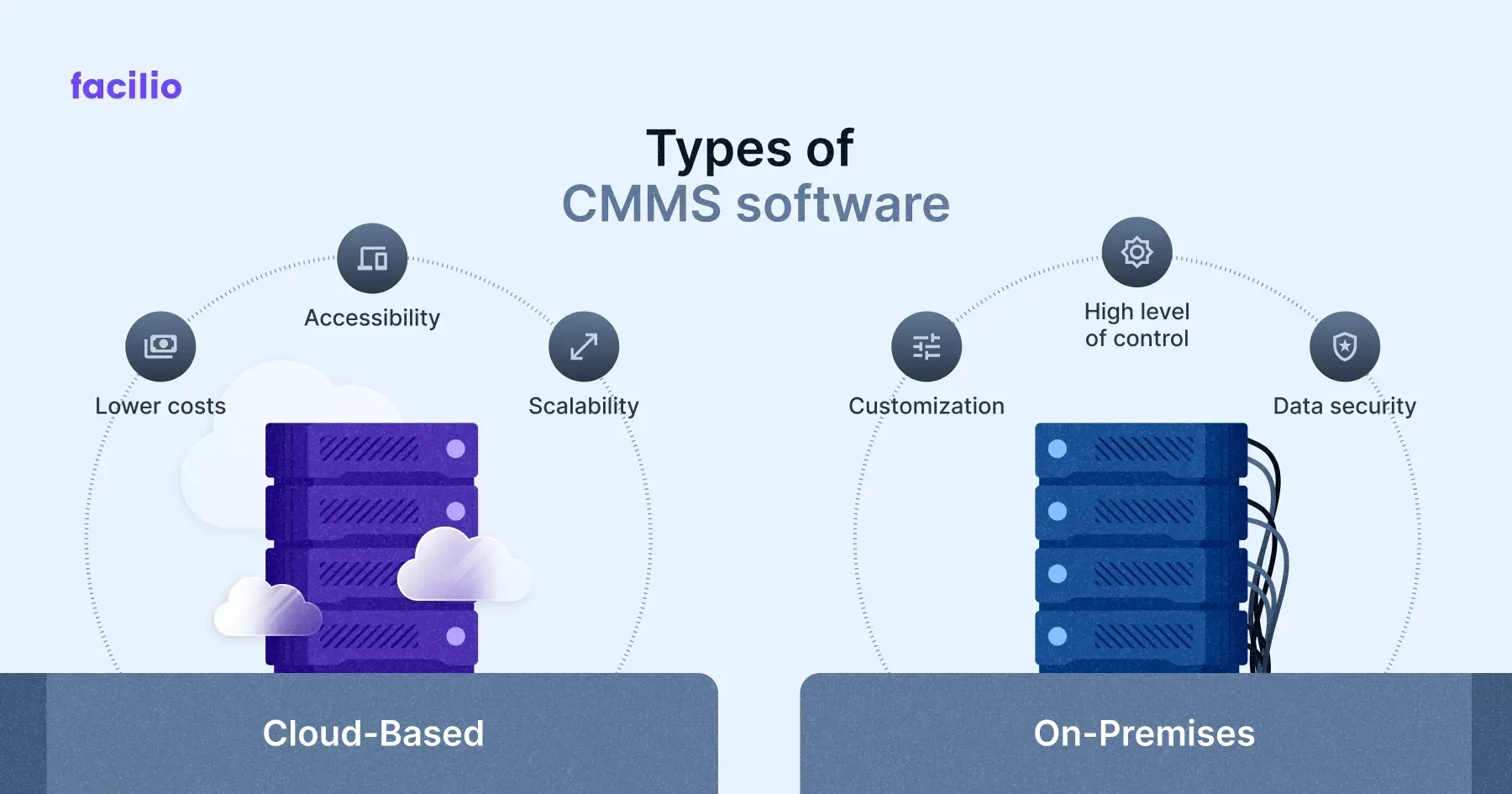

What are the types of CMMS? (On-Premise vs. Cloud-Based CMMS)

A computer-based maintenance management system (CMMS) can be classified into two types based on where they are installed and operated.

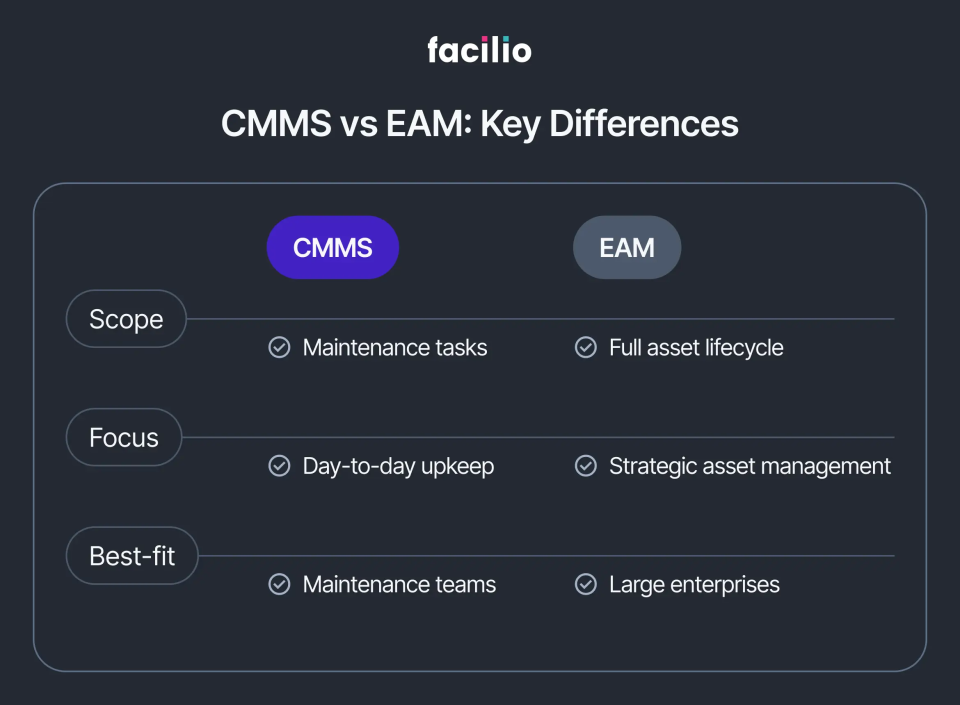

CMMS vs EAM: What is the difference?

Many teams talk about CMMS and EAM as if they’re the same thing.

But in reality, they solve different problems and have clear distinctions.

A CMMS helps you stay on top of everyday maintenance work — like scheduling, repairs, and tracking equipment health.

But an EAM goes even further. It looks at the big picture of assets over their entire life, from when they’re purchased to when they’re retired.

Knowing the difference between CMMS and EAM makes it easier to pick the system that actually fits your needs.

How to choose a CMMS software: A 7-step guide to success

With so many CMMS vendors in the market, it’s easy to get lost in feature lists and sales pitches. A structured checklist can help you cut through the noise and focus on what really matters.

How to choose a CMMS software - CMMS Evaluation Guide for Enterprises

You can also download the printable version of the CMMS evaluation guide to identify and choose the best CMMS software for your needs.

Here’s what to look for when evaluating CMMS software:

a) Define your requirements clearly

- Start with your team’s pain points: Are you struggling with unplanned downtime, difficulty tracking assets, or poor reporting?

- Separate must-haves (preventive scheduling, mobile work orders, asset history tracking) from nice-to-haves (AI-driven analytics, IoT integrations).

- Involve both supervisors and frontline technicians. In the US, where skilled labor shortages are common, ease of use is critical for adoption.

b) Check integration capabilities

- US organizations often run ERP systems like SAP or Oracle, and BMS platforms for HVAC and energy management. Make sure your CMMS can integrate with these systems.

- Look for solutions that support open APIs or have prebuilt connectors to avoid high custom integration costs.

- Future-proof your choice by confirming IoT sensor compatibility (commonly used in US manufacturing and healthcare).

c) Evaluate usability and adoption (Check mobile usability)

- Field technicians in the US are mobile-first. Test whether the CMMS has a reliable iOS/Android mobile app that works offline.

- During demos, involve end-users to gauge ease of navigation and speed of updating work orders.

- Look for role-specific dashboards — managers in facilities, property, or hospitals need KPI tracking, while techs need quick job instructions.

d) Assess vendor support and training

- Strong customer support is non-negotiable in the US market. Check if the vendor offers 24/7 support or dedicated account managers.

- Ask about onboarding and training resources — web-based training is common, but in-person training may be required for larger US facilities.

- Evaluate the vendor’s US customer base. References from local industries (e.g., hospitals in New York, universities in California, retail chains in Texas) are valuable proof points.

e) Understand scalability and pricing

- Confirm the software can scale from one site to multiple across states. Multi-site support is crucial for US enterprises with dispersed operations.

- Compare pricing models: per-user, per-asset, or per-site. In the US, subscription-based SaaS pricing is most common and often easier to budget for.

- Watch for hidden costs: advanced analytics, integrations, and storage are frequent add-ons in US contracts.

f) Test reporting and insights

- The right CMMS should track standard maintenance KPIs like MTTR, MTBF, and planned vs reactive ratio.

- US facility managers also prioritize OSHA and the Joint Commission compliance metrics (safety inspections, incident logs) — check that these can be reported easily.

- Dashboards should be customizable so teams can highlight the KPIs most relevant to their industry.

g) Verify compliance and security features

- For US healthcare and education, ensure the CMMS is HIPAA-compliant if sensitive data is handled.

- Check for SOC 2 or ISO 27001 certifications, which US enterprises often require during vendor selection.

- Ask about role-based permissions and cloud hosting — many US firms prefer vendors with servers hosted in the US to meet data residency requirements.

The best CMMS isn’t just software, it’s an investment for good vendor relationships. So always look for a provider that understands your industry, has a track record of success, and will grow with you as your operations evolve.

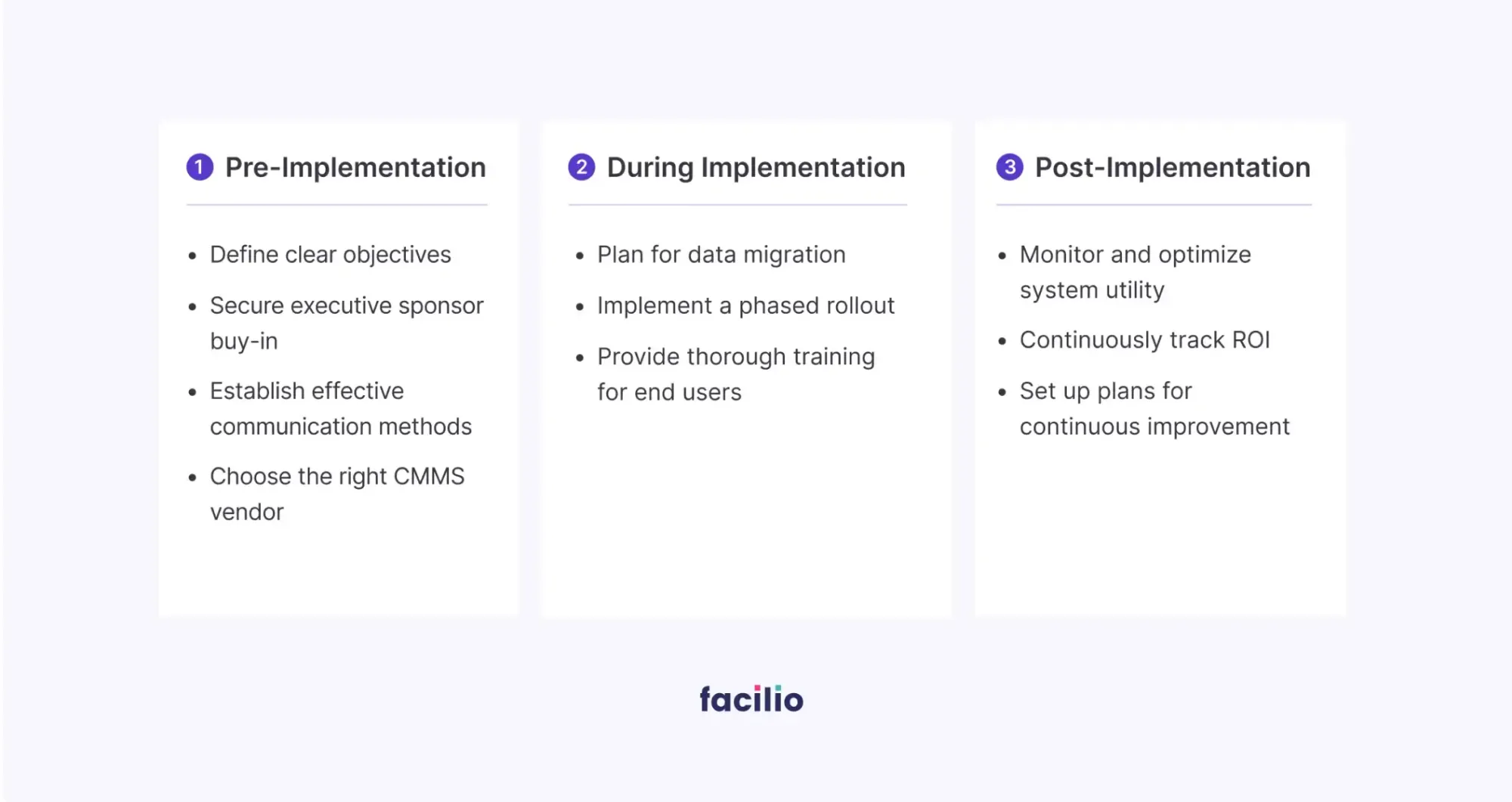

How to implement a CMMS the right way

Buying a CMMS is only half the battle; success depends on rolling it out in a way your team will actually use.

Many projects fail not because the software is weak, but because adoption and processes aren’t aligned.

Industry trends show that nearly 70% of CMMS implementations underperform when organizations skip steps like data cleanup or user training. By prioritizing clean data, phased rollouts, and user buy-in, you set your CMMS project up for long-term success.

Here’s how to get the CMMS implementation right:

a) Start with clear goals: Set measurable targets for the first 6–12 months, like cutting downtime by 20%, improving preventive maintenance completion, or centralizing asset data.

b) Involve your team early: Frontline techs and supervisors use the system daily. Bring them into setup, training, and pilots to drive adoption and reduce resistance.

c) Clean and migrate data carefully: Audit asset registers, work order logs, and spare parts lists. Remove duplicates, standardize naming, and fill gaps before migration — clean data prevents future headaches.

d) Configure to match workflows: Adapt the CMMS to fit real-world processes. Customize work order types, approvals, and notifications so teams don’t feel forced into rigid software rules.

e) Train and support continuously: Offer role-based training for technicians, managers, and admins. Provide quick guides, refresher sessions, and vendor support. Many US firms also appoint a CMMS champion to drive adoption.

f) Roll out in phases: Avoid “big bang” launches. Start small — one site or department — prove value, then expand across the organization.

g) Monitor and optimize: Track KPIs like work order completion, response times, and preventive vs reactive ratios. Use these insights to refine processes and prove ROI to leadership.

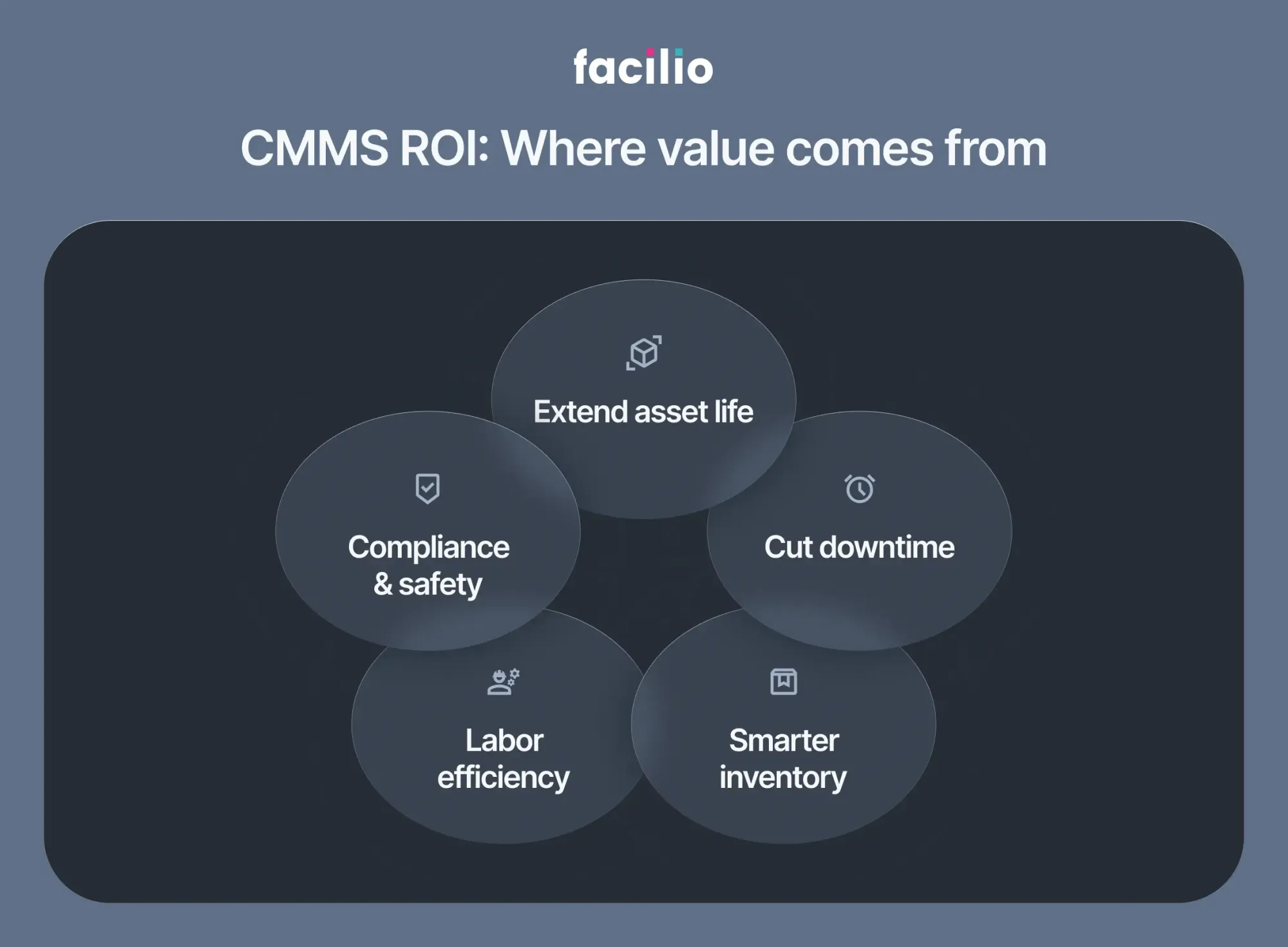

How to measure the ROI of a CMMS

In the US, CMMS adoption isn’t about “nice to have” features; it’s about proving hard numbers.

Facility managers, CFOs, and operations leaders expect measurable returns from reduced downtime, lower maintenance spend, and longer asset life.

The formula is simple: CMMS ROI = (CMMS Value – CMMS Cost)

- CMMS Value = savings across operations

- CMMS Cost = subscription fees, onboarding, integrations

Where CMMS creates value (How a modern CMMS drives RoI)

a) Extending asset life – Preventive maintenance stretches equipment lifecycles, defers replacement costs, and reduces capital spend. Even adding two years to a $500,000 chiller is a six-figure saving.

b) Cutting downtime – Every hour of downtime hits revenue. A CMMS minimizes outages with preventive schedules and faster response, often the biggest ROI driver.

c) Smarter inventory control – Overstocking and emergency orders drain cash. CMMS tools optimize spare parts use, cutting waste and freeing up capital.

d) Labor efficiency – With US labor shortages, efficiency matters. CMMS reduces paperwork, lowers overtime, and helps technicians focus on high-value work.

e) Compliance and safety – Avoiding OSHA fines, safety incidents, and failed audits directly improves ROI. Automated schedules and digital records keep operations audit-ready.

A) US benchmarks: Most enterprises see a 25%–300% ROI in the first year, depending on maintenance maturity and adoption rates.

B) UK benchmarks: ROI tends to be more conservative in the first year, with savings coming from improved compliance and efficiency. Longer-term benefits (3–5 years) include asset lifecycle extension and energy savings, which align with the UK’s strong sustainability push.

How much does CMMS software cost? A realistic pricing guide

When evaluating CMMS pricing, numbers can vary quite a bit depending on size, features, deployment type, and support. To get a realistic view, we spoke with industry experts, reviewed product listings on software marketplaces, and scanned through user reviews and ratings across multiple platforms.

The following ranges (as of 2025) reflect those insights and give a fair picture of what you can expect and what factors will influence where your cost will land.

Typical price ranges of CMMS

These often catch people off guard:

1) Does “mobile app” cost extra? Is offline mode included or an add-on?

2) Are feature modules like advanced analytics, downtime alerts, or condition-based maintenance locked behind premium tiers?

3) What are the charges for integrations (API access), data migration, or custom reports?

4) Are support and updates included, or extra?

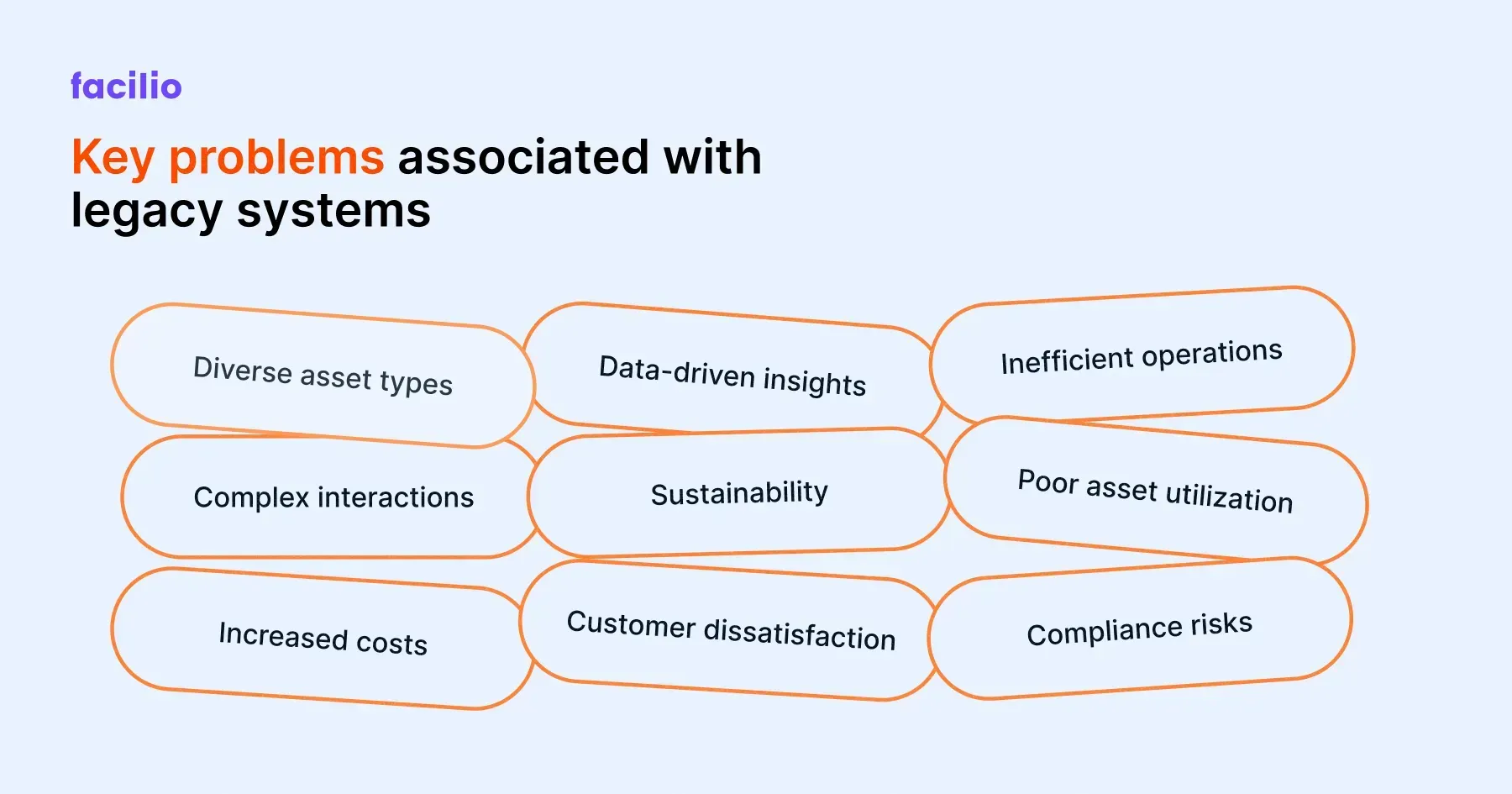

What are the limitations of your legacy CMMS software?

While legacy CMMS platforms were once sufficient for basic maintenance tracking, they fall short in meeting the demands of today’s fast-moving, data-driven facility operations.

Older tools struggle to keep up as buildings, systems, and expectations grow more complex.

a) Hard to learn – Outdated interfaces require heavy training, slowing adoption.

b) Painful data migration – Moving years of records is complex, with little built-in support.

c) Poor integrations – Legacy tools rarely connect with ERP, IoT, or BMS, creating silos.

d) Limited mobility – Technicians can’t update on mobile, delaying visibility.

e) Lack of real-time insights – Reports are static, offering no cross-site or KPI visibility.

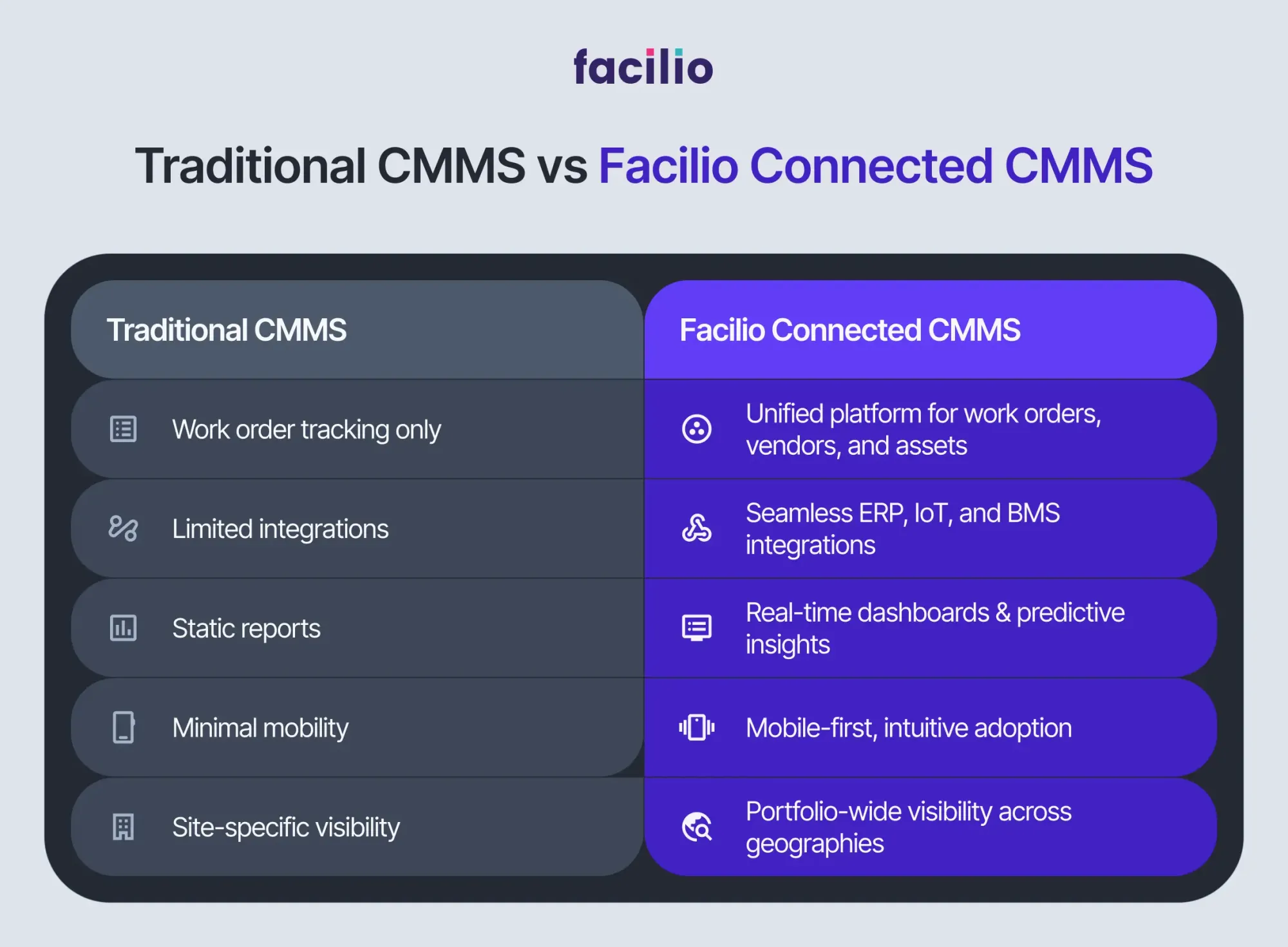

How facility leaders worldwide rely on Facilio’s Connected CMMS

Unlike traditional CMMS platforms that stop at work order management, Facilio’s Connected CMMS solution unifies operations across sites, integrates seamlessly with other business systems, and delivers real-time insights at scale. It’s designed not just for maintenance teams, but for enterprise leaders who need visibility, agility, and smarter decision-making across their portfolios.

Take the example of warehouses and distribution centers, where operators are increasingly turning to AI and automation to keep facilities running efficiently — from coordinating vendors to maintaining critical assets.

Skeens Warehouse Services, a third-party facility support firm based in Indiana, partnered with Facilio to simplify how it manages work orders and vendor communications.

“What used to take multiple tools, emails and manual steps is now streamlined and fully visible in one place. We’ve not only eliminated hours of manual coordination but are now better equipped to scale our services for new clients and international expansion.”

— Riley Skeens, Vice President of Operations at Skeens Warehouse Services.

How Facilio takes it further

What Skeens achieved reflects the core value of Facilio’s Connected CMMS:

- One source of truth for managing work orders, vendors, and assets across facilities.

- Portfolio-wide visibility that scales easily across sites and geographies.

- Seamless integrations with ERP, IoT, and building systems to break down silos.

- Fast adoption with intuitive, mobile-first workflows.

- Future-ready capabilities, including predictive maintenance and sustainability tracking.

While even the best of CMMS platforms stop at basic work order management, Facilio helps enterprises transform maintenance and operations into a strategic advantage. It reduces costs today and prepares for the demands of tomorrow.

Book a demo today and discover how Facilio helps you reduce costs, extend asset life, and build smarter, future-ready facilities.

Frequently Asked Questions

1. What does CMMS stand for?

CMMS means Computerized Maintenance Management System. It is a software used to manage and streamline facility maintenance tasks, schedules, and asset tracking.

2. Who needs a CMMS?

Any organization or entity that works within a built environment with assets that need regular maintenance need a CMMS. It includes manufacturing plants, hospitals, facilities management, commercial real estate, and facility management companies.

3. Is CMMS the same as ERP?

No. The CMMS mainly focuses on maintenance management. It helps manage work orders, track assets, schedule preventive maintenance, manage inventory, and generate maintenance reports. ERP (Enterprise Resource Planning), on the other hand, is a broader system that integrates various business processes, like finance, HR, supply chain, etc.

4. What is the difference between CMMS and EAM software?

CMMS is primarily used for maintenance management, while EAM (Enterprise Asset Management) software covers the entire lifecycle of assets, including acquisition, operation, maintenance, and disposal.

5. What is the cost of CMMS?

CMMS costs vary based on several factors like deployment, number of users and number of features. The price of cloud-based point solutions typically range from $30 to $150 per user per month, while on-premise solutions may involve higher upfront costs and additional expenses for implementation and support.

6. What is the difference between CAFM and CMMS?

CAFM (Computer-Aided Facility Management) focuses on managing facilities, space planning, and building operations, while CMMS is primarily centered on maintenance management of assets and equipment.

7. What are the industries that benefit from CMMS?

Industries like manufacturing, healthcare, facilities management, utilities, and real estate benefit from CMMS by improving maintenance efficiency, reducing downtime, and extending asset life.

8. Why do Legacy CMMS fail?

CMMS implementations often fail due to lack of management support, poor user adoption, inadequate training, and selecting a system that doesn’t align with the organization’s needs.

9. What is a maintenance management system, and how does it differ from CMMS?

A Maintenance Management System (MMS), often synonymous with CMMS (Computerized Maintenance Management System), is a software platform designed to help organizations effectively manage and optimize their maintenance activities. It consolidates data, simplifies workflows, and enhances the efficiency of maintaining assets, equipment, and facilities.