Stricter EPA Refrigerant Regulations in 2025: What You Need to Know

The Environmental Protection Agency (EPA) has introduced major updates to refrigerant management regulations, effective January 2025.

These changes include higher fines, stricter compliance rules, and a phase-down of high-GWP refrigerants under the AIM Act and EPA Section 608 of the Clean Air Act.

Stricter HFC Restrictions & Refrigerant Phaseout

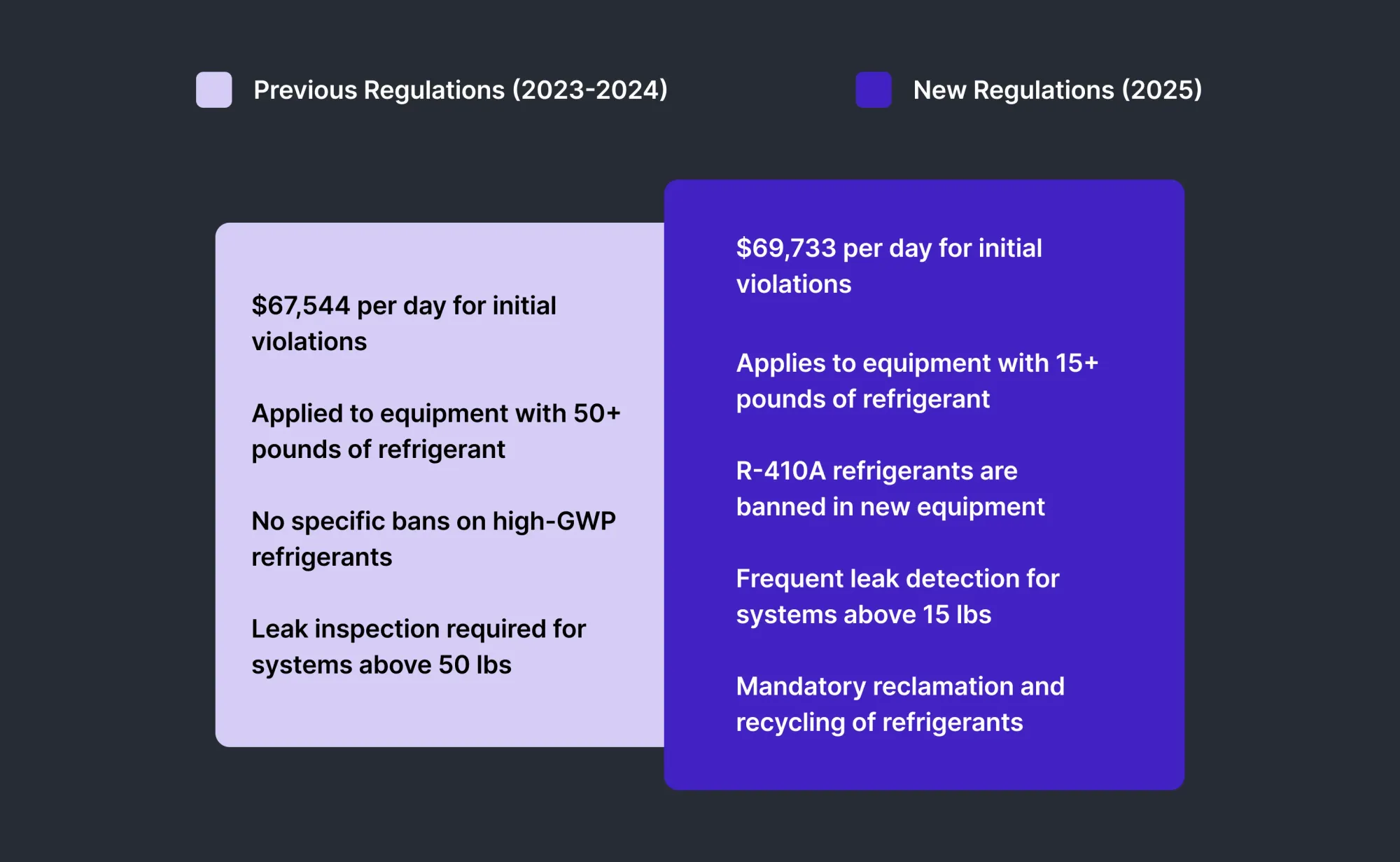

To curb environmental damage, the EPA has lowered the threshold for regulated refrigeration assets:

1. New threshold: Equipment containing 15+ pounds of refrigerant (previously 50+ lbs)

2. Phasing out high-GWP refrigerants (e.g., R-410A) in favor of eco-friendly alternatives (R-32, R-454B)

3. January 1, 2025: Restrictions on high-GWP HFCs for air conditioning and refrigeration take effect

Rising Penalties for Non-Compliance

The EPA has increased civil penalties for refrigerant violations:

- Up to $69,733 per day for initial violations

- $57,617 per day per violation thereafter

- 1.02% fine increase from 2024 to adjust for inflation

Old EPA Regulations vs New EPA Regulations: What has Changed?

Who’s Affected by The Stricter Regulations?

These regulatory changes impact a wide range of industries that handle refrigerants, including:

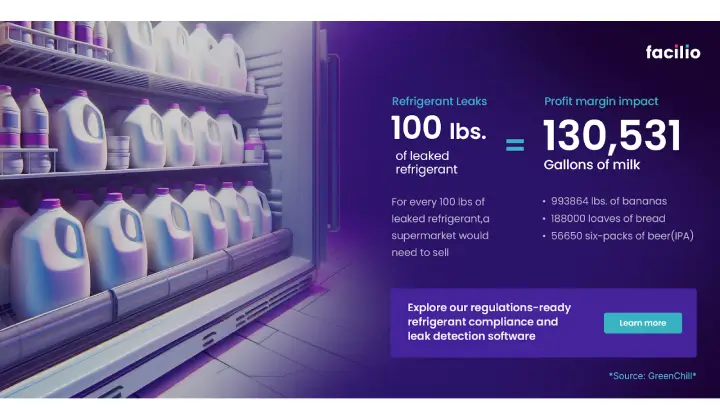

Retailers & Grocery Stores: Supermarkets, convenience stores, and food retail businesses with refrigeration units

Commercial Buildings & Facility Managers: Large office spaces, malls, hotels, and hospitals with HVAC systems

Manufacturing & Cold Storage Warehouses: Businesses that store or transport perishable goods

HVAC Contractors & Technicians: Service providers responsible for the installation, repair, and maintenance of refrigerant-based equipment

Why This Matters for Businesses?

Retailers, facility managers, and HVAC service providers must comply with stricter monitoring, leak detection, and reporting mandates to avoid fines and operational risks. Outdated maintenance processes and manual inspections won’t cut it anymore.

To ensure compliance and operational efficiency, businesses must adopt software-driven refrigerant monitoring and automated compliance solutions.

Next, we’ll break down the AIM Act regulations and explore how advanced refrigerant tracking solutions can keep you ahead of the curve.

Read More:

- Refrigerant Compliance Management Software

- Refrigerant Leak Detection: Methods of Detection and Regulatory Requirements

Summary of the EPA HVAC regulation updates - 2025

Here’s a clear summary of the 2025 EPA HVAC regulation updates in a consumable format.

Mandatory Automatic Leak Detection (ALD) Systems:

- Applicability: Owners or operators of industrial process refrigeration and commercial refrigeration appliances with a full charge of 1,500 pounds or more of refrigerants containing regulated substances or substitutes with a Global Warming Potential (GWP) greater than 53 must install and use ALD systems.

- Compliance Deadlines:

- New Installations (On or After January 1, 2026): ALD systems must be installed upon or within 30 days of appliance installation.

- Existing Installations (Between January 1, 2017, and January 1, 2026): ALD systems must be installed by January 1, 2027.

- Maintenance Requirements: ALD systems must be installed per manufacturer instructions and audited and calibrated annually.

Leak Repair Provisions (40 CFR Part 82, Subpart F):

- Scope: Applies to appliances with a full charge of 50 or more pounds of class I or class II refrigerants.

- Leak Rate Thresholds: Owners or operators must take corrective action when an appliance exceeds the applicable leak rate.

- Recordkeeping: Meticulous documentation of leak rate calculations, repair efforts, and verification tests is required.

Zero-Tolerance Stance on Leak Thresholds:

The EPA enforces strict compliance with federal leak thresholds. Precision in leak rate calculations and diligent record-keeping are essential to avoid penalties.

Facilio Connected Refrigeration – The Tech That Has Your Back 24/7

With regulations tightening, facility managers need to stay ahead of the game. Here’s what you should focus on:

- Leak Detection & Repair: For systems with over 1,500 pounds of refrigerant, ALD systems are a must to catch leaks early.

- Reclamation: Minimize HFC emissions by reclaiming and reusing refrigerants wherever possible.

- Recordkeeping & Reporting: As the AIM Act brings stricter regulations, it’s crucial to adopt innovative FM technology to track and report activities effectively.

Facilio’s connected refrigeration solution is built to support facility managers in tackling these challenges head-on.

Just ask King Kullen, a leading retailer that saw up to 20% energy savings and reduced compliance risks by using Facilio’s real-time leak detection and smart monitoring. They achieved ROI in under 6 months, demonstrating how Facilio not only helps you stay compliant but also optimizes operations and saves money.

When it comes to managing refrigerant leaks, compliance, and risk, Facilio is the tech that does it all.

Ready to make compliance easy and your systems smarter?

More from Facilio